NWT Sports Professional World Athletics Certificate Prefabricated Rubber Run Run Track

Abubuwan Dabarun Gudun Rubber da aka riga aka kera

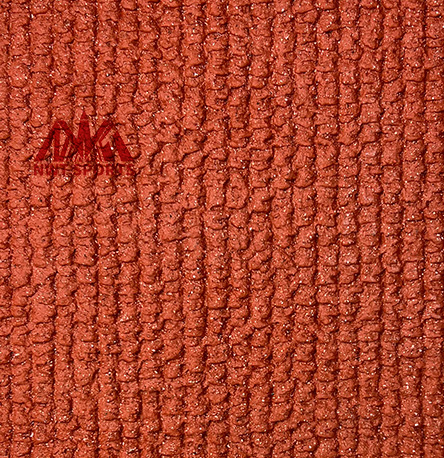

Waƙar mu ta robar tana da mafi kyawun aiki akan juriyar tsufa da ɗaukar girgiza saboda mun zaɓi mafi kyawun abu da fasaha na ci gaba. A cikin tsarin zane na samfurin, an yi la'akari da bukatun halittu na 'yan wasa: Tsarin gida mai girma mai girma uku-kamar tsarin ciki yana sa titin jirgin sama yana da kyakkyawan elasticity, ƙarfi, ƙarfi, da tasirin girgiza kuma yadda ya kamata ya rage gajiyar tsoka na dan wasa da ƙananan rauni.

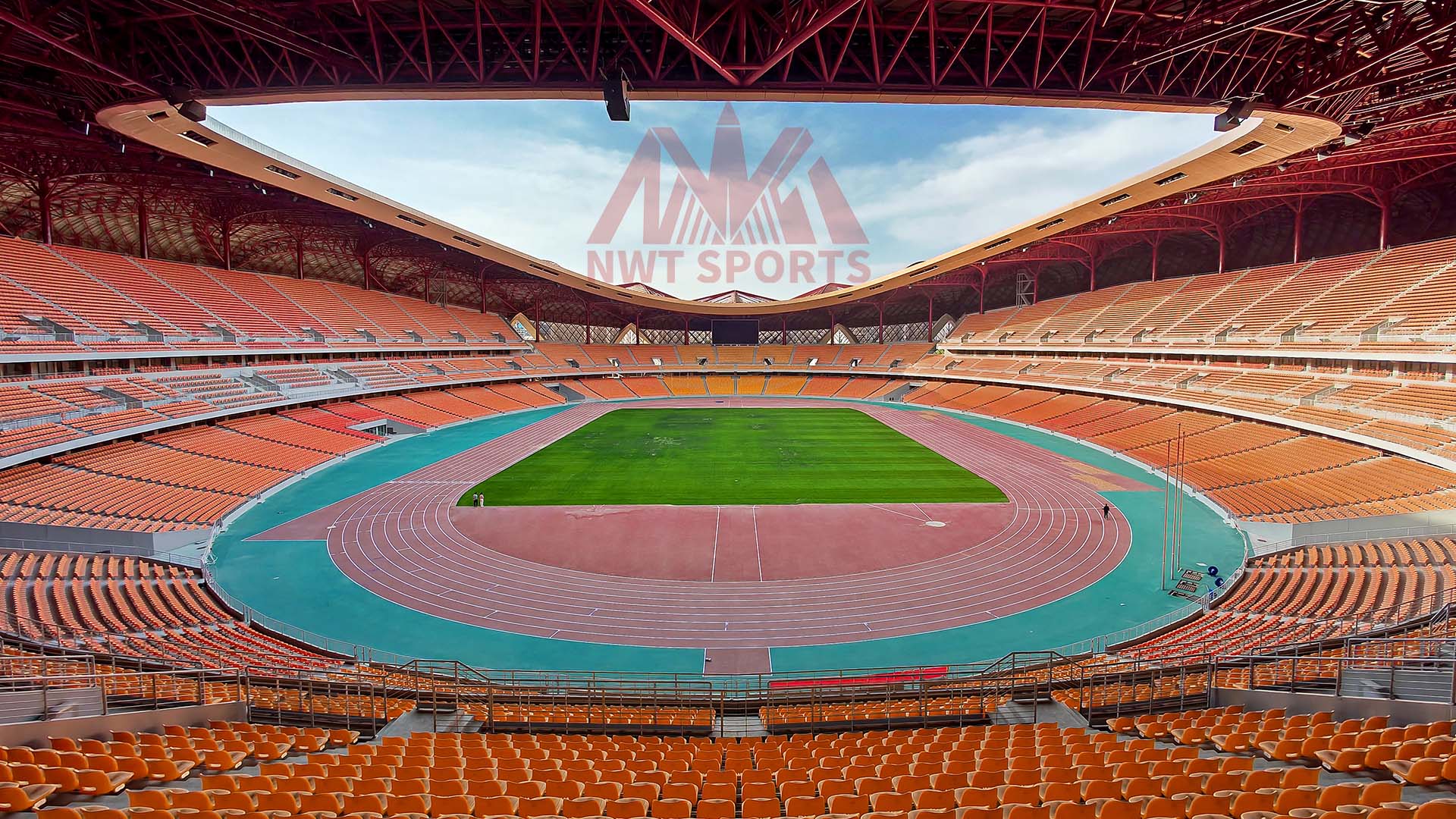

Aikace-aikacen Waƙar Gudun Rubber da aka riga aka yi

Ma'auni na Gudun Rubber Prefabricated

| Ƙayyadaddun bayanai | Girman |

| Tsawon | mita 19 |

| Nisa | 1.22-1.27 mita |

| Kauri | 8 mm - 20 mm |

| Launi: Da fatan za a koma ga katin launi. Launi na musamman kuma mai sasantawa. | |

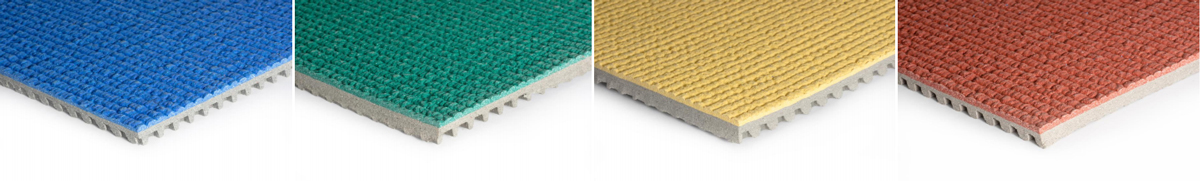

Katin Launi mai Gudun Rubber wanda aka riga aka yi

Tsare-tsaren Waƙar Gudun Rubber da aka riga aka yi

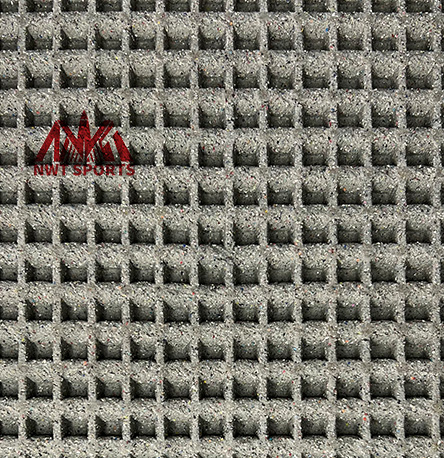

Samfurin mu ya dace da manyan makarantun ilimi, cibiyoyin horar da wasanni, da makamantan wuraren. Maɓallin maɓalli daga 'Training Series' ya ta'allaka ne a cikin ƙirar ƙirar ƙasan sa, wanda ke fasalta tsarin grid, yana ba da madaidaicin matakin laushi da ƙarfi. An tsara ƙananan Layer azaman tsarin saƙar zuma, wanda ke haɓaka matakin ƙaddamarwa da haɓakawa tsakanin kayan waƙa da saman tushe yayin watsa ƙarfin sake dawowa da aka haifar a lokacin tasiri ga 'yan wasa, ta haka ya rage tasirin da aka samu yayin motsa jiki, kuma Wannan yana canzawa zuwa isar da kuzarin motsa jiki, wanda ke haɓaka ƙwarewar ɗan wasa da haɓakar ɗan wasa, haɓaka ƙwarewar ɗan wasa da ingantaccen aiki. sake dawo da karfi da aka haifar yayin tasiri ga 'yan wasa, yana mai da shi zuwa kuzarin motsa jiki na gaba. Wannan yadda ya kamata ya rage tasiri a kan haɗin gwiwa yayin motsa jiki, yana rage raunin da 'yan wasa ke yi, kuma yana haɓaka ƙwarewar horo da gasa.

Cikakkun Bayanan Rubutun Gudun Rubutun da aka riga aka kera

Layer mai jurewa sawa

Kauri: 4mm ± 1mm

Tsarin jakar iska na saƙar zuma

Kusan 8400 perforations a kowace murabba'in mita

Na roba tushe Layer

Kauri: 9mm ± 1mm

Shigar da Waƙar Gudun Rubber Prefabricated