Kafin gini,prefabricated roba guje hanyas na buƙatar takamaiman matakin taurin ƙasa, saduwa da ƙa'idodin taurin kafin a iya ci gaba da gini. Don haka, dole ne a ƙarfafa tushen tushe na waƙoƙin roba da aka riga aka kera.

Concrete Foundation

1. Bayan kammala kafuwar, farfajiyar simintin kada ta kasance mai santsi sosai, kuma kada a sami wasu abubuwa kamar yashi, bawo, ko tsagewa.

2. Flatness: Gabaɗaya ƙimar izinin wucewa yakamata ya kasance sama da 95%, tare da juriya na tsakanin 3mm akan madaidaiciyar 3m.

3. Tulle: Ya kamata ya hadu da ƙayyadaddun fasaha na wasanni ( gangaren gefe bai fi 1% ba, gangaren tsayin da ba zai fi 0.1%) ba.

4. Ƙarfin ƙarfi: R20> 25 kg / santimita murabba'in, R50> 10 kg / santimita murabba'in.

5. Tushen tushe ya kamata ya kasance ba tare da toshe ruwa ba.

6. Compaction: Surface compaction density ya kamata a kan 97%.

7. Lokacin kulawa: Sama da 25 ° C zafin jiki na waje don kwanaki 24; tsakanin 15 ° C da 25 ° C zafin jiki na waje don kwanaki 30; kasa da 25°C a waje zafin jiki na kwanaki 60 (shayarwa akai-akai a lokacin kiyayewa don cire abubuwan alkaline daga siminti maras tabbas).

8. Matsakaicin murfin ya kamata ya zama santsi da sauye-sauye tare da waƙa ba tare da matakai ba.

9. Kafin shimfiɗa waƙoƙin roba da aka riga aka kera, layin tushe ya kamata ya zama maras mai, toka, da bushewa.

Asphalt Foundation

1. Tushen tushe dole ne ya kasance ba tare da fasa ba, alamun abin nadi na fili, tabon mai, guntun kwalta mara gauraya, tauri, nutsewa, fatattaka, saƙar zuma, ko kwasfa.

2. Tushen tushe ya kamata ya kasance ba tare da toshe ruwa ba.

3. Flatness: Matsakaicin wucewa don flatness yakamata ya kasance sama da 95%, tare da juriya tsakanin 3mm akan madaidaiciyar 3m.

4. Tudu: Ya kamata ya hadu da ƙayyadaddun fasaha na wasanni ( gangaren gefe bai fi 1% ba, gangaren tsayin da ba zai fi 0.1%) ba.

5. Ƙarfin ƙwaƙwalwa: R20> 25 kg / santimita murabba'in, R50> 10 kg / santimita murabba'in.

6. Compaction: Surface compaction yawa ya kamata a kan 97%, tare da bushe iya aiki kai kan 2.35 kg / lita.

7. Kwalta laushi batu> 50 ° C, elongation 60 cm, allura shigar zurfin 1/10 mm> 60.

8. Kwalta ta thermal kwanciyar hankali coefficient: Kt = R20 / R50 ≤ 3.5.

9. Ƙimar faɗaɗa girma: <1%.

10. Yawan sha ruwa: 6-10%.

11. Lokacin kulawa: Sama da 25 ° C zafin jiki na waje don kwanaki 24; tsakanin 15 ° C da 25 ° C zafin jiki na waje don kwanaki 30; ƙasa da 25°C na waje zafin jiki na kwanaki 60 (dangane da abubuwan da ba su da ƙarfi a cikin kwalta).

12. Matsakaicin murfin ya kamata ya zama santsi da sauye-sauye tare da waƙa ba tare da matakai ba.

13. Kafin shimfiɗa waƙoƙin da aka riga aka tsara na roba, tsaftace tushen tushe da ruwa; Tushen ya kamata ya zama maras mai, toka, da bushewa.

Aikace-aikacen Waƙar Gudun Rubber da aka riga aka yi

Ma'auni na Gudun Rubber Prefabricated

| Ƙayyadaddun bayanai | Girman |

| Tsawon | mita 19 |

| Nisa | 1.22-1.27 mita |

| Kauri | 8 mm - 20 mm |

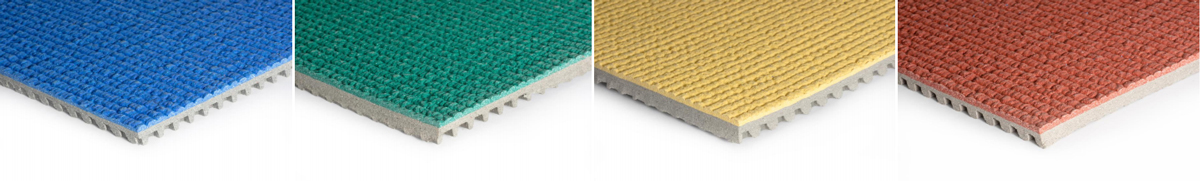

| Launi: Da fatan za a koma ga katin launi. Launi na musamman kuma mai sasantawa. | |

Katin Launi mai Gudun Rubber wanda aka riga aka yi

Cikakkun Bayanan Rubutun Gudun Rubutun da aka riga aka kera

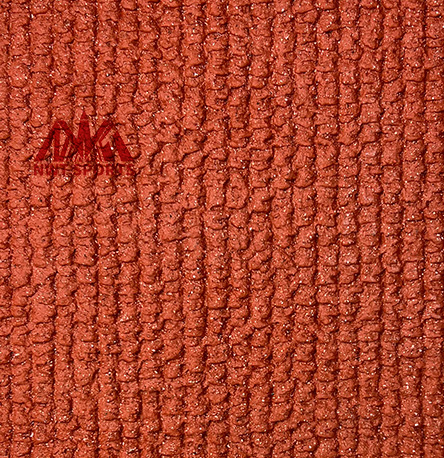

Layer mai jurewa sawa

Kauri: 4mm ± 1mm

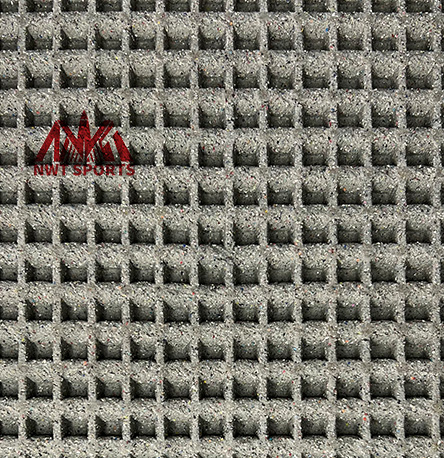

Tsarin jakar iska na saƙar zuma

Kusan 8400 perforations a kowace murabba'in mita

Na roba tushe Layer

Kauri: 9mm ± 1mm

Shigar da Waƙar Gudun Rubber Prefabricated

Lokacin aikawa: Yuni-26-2024