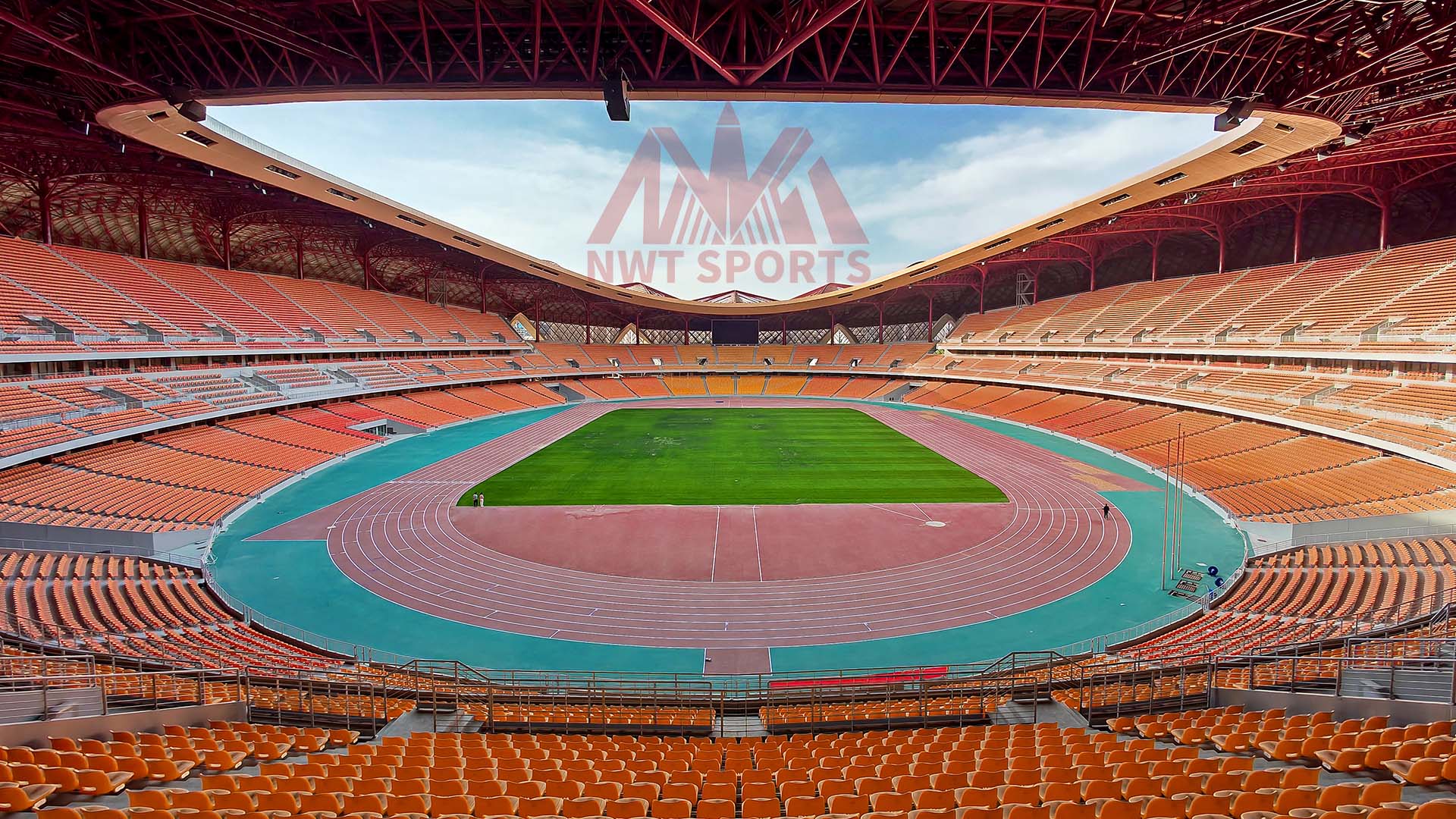

NWT Wasanni, babban suna a cikikamfanonin shigar waƙa masu gudana, ƙware wajen ƙirƙirar waƙoƙi masu inganci, dorewa don wurare daban-daban. Ko kuna buƙatar waƙar roba don makaranta, ƙwararriyar waƙar guje-guje ta 400m, ko hanyar cikin gida mai tsayin mita 200, muna ba da sabis na ƙwararru waɗanda suka dace da bukatunku.

Mataki 1: Tsara & Tsara

Mataki na farko a kowane shigarwar waƙa mai gudana shine tsarawa da ƙira sosai. A Wasannin NWT, muna farawa da cikakken kimantawar rukunin yanar gizon, nazarin abubuwa kamar ƙasa, magudanar ruwa, da isarwa. Wannan yana ba mu damar ƙirƙirar ƙira na musamman wanda ya dace da takamaiman bukatun wurin da kuke. Ko daidaitaccen hanyar gudu na mita 400 ko tsarin al'ada don ƙaramin sarari, ƙirarmu tana ba da fifikon aiki da tsawon rai.

Mataki 2: Shirye-shiryen Yanar Gizo

Shirye-shiryen wurin da ya dace yana da mahimmanci don nasarar kowace hanya mai gudana. Wannan mataki ya kunshi share wurin tarkace da ciyayi, sannan sai a sanyawa ko inganta tsarin magudanar ruwa don hana zubar ruwa. Gidan da aka shirya da kyau yana tabbatar da dorewa da aikin waƙar, yana mai da shi mahimmanci don amfani na dogon lokaci.

Mataki 3: Gina Tushen

Tushen hanyar gudu yana da mahimmanci kamar saman kanta. Wasannin NWT yana amfani da kayan inganci kamar dutsen da aka murƙushe ko tara don ƙirƙirar tushe mai tsayayye. Wannan tushe an daidaita shi a hankali kuma an haɗa shi don samar da tallafin da ya dace don saman waƙar roba. Tushen da aka gina da kyau shine mabuɗin don hana al'amura na gaba kamar tsagewa ko filaye marasa daidaituwa.

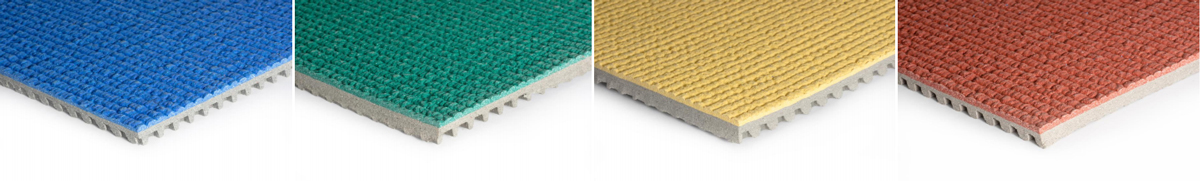

Katin Launi mai Gudun Rubber wanda aka riga aka yi

Mataki na 4: Shigar da Surface Track Surface

Da zarar tushe ya shirya, za mu ci gaba da shigar da filin waƙa na roba. Wannan ya haɗa da amfani da yadudduka da yawa na polyurethane ko roba, kowane Layer ya shimfiɗa sosai kuma an haɗa shi don ƙirƙirar ƙasa mai juriya da ɗorewa. An tsara filin waƙa na roba don samar da 'yan wasa mafi kyaun motsi, kwantar da hankali, da sauri, wanda ya sa ya dace da horo da kuma gasa abubuwan.

Mataki na 5: Alama & Kammala

Bayan filin waƙa na roba ya kasance a wurin, matakan ƙarshe sun haɗa da sanya alamar layin da amfani da maganin gamawa. Ana amfani da alamar layin bisa ga ƙa'idodin ƙasashen duniya ko na ƙasa, tabbatar da cewa waƙar tana shirye don amfani mai gasa. Maganin gamawa yana haɓaka juriyar zamewar waƙar da tsayin daka gabaɗaya, yana tabbatar da cewa zai iya jure wahalar amfani yau da kullun.

Kammalawa

Gudun shigar waƙa wani tsari ne mai rikitarwa wanda ke buƙatar ƙwarewa, daidaito, da hankali ga daki-daki. Wasannin NWT ya himmatu wajen isar da mafita na maɓalli wanda ya dace da takamaiman buƙatun kowane wuri, yana tabbatar da babban aiki da inganci mai dorewa. Daga tsarawa da ƙira zuwa shigarwa da ƙarewa, muna ɗaukar kowane bangare na tsari, yana mai da mu ɗaya daga cikin manyan kamfanonin shigar da waƙa a cikin masana'antar.

Cikakkun Bayanan Rubutun Gudun Rubutun da aka riga aka kera

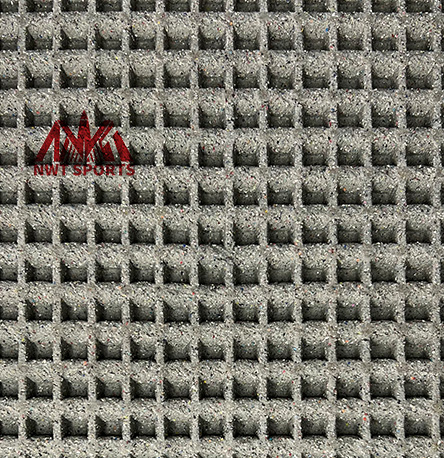

Tsarin jakar iska na saƙar zuma

Kusan 8400 perforations a kowace murabba'in mita

Na roba tushe Layer

Kauri: 9mm ± 1mm

Shigar da Waƙar Gudun Rubber Prefabricated

Lokacin aikawa: Agusta-30-2024